About us

Machine-building plant "Tonar" is the largest Russian manufacturer of trailed and semi-trailer equipment, the only Russian manufacturer of dump trucks and high-capacity road trains. For more than 25 years, the factory produces quality and marketable technology. The history of the plant began with the production of trailers for cars. The official date of Foundation is 30 November 1990.

Main stages of development:

Trailers for cars

Start of production of trade stalls "TONAR»

First full-size semi-trailer

Start of production of isothermal bodies

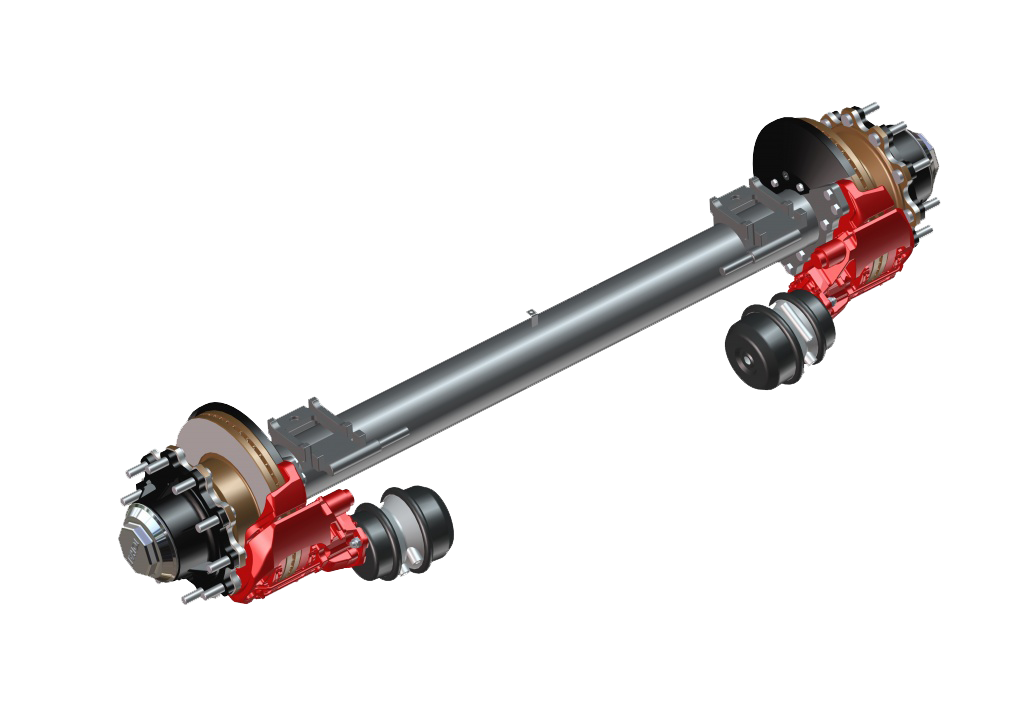

Production of own axial units

Peak sales of dump semi-trailers

The first models of agricultural machinery

Start of production of dump trucks with side unloading.

Released the first Russian mining truck

New on the Russian market – cassette dump truck

Released a new, unparalleled in Russia, a giant road train as part of a mining tractor and articulated dump semi-trailer with two bodies, capable of carrying more than 130 tons of cargo on technological roads!

On may 19, 2017, at the annual Presentation of the TONAR plant, an upgraded version of the Tonar-45251 technological (quarry) dump truck was presented

MOH "Tonar" for the third year in a row was recognized as the best company that manufactures import-substituting products, presenting aluminum semi-trailer-grain Tonar-9523!

Modern production

The basis of the enterprise is a production complex in the village of Gubino, Orekhovo-Zuevsky district of the Moscow region. The factory covers an area of 19.1 Ha. Total area - 44 944 sq. m. the Warehouse of finished products - 6 Ha. The plant employs more than 700 people.

Production covers the entire technological cycle: from development, manufacturing, Assembly to sales of finished products and service.

Release of new models is accompanied by continuous modernization of production. In recent years, the plant has installed robotic systems for plasma cutting of metal, welding of bodies, sides, assemblies and axle beams.

Own design Bureau is a team of professionals with extensive experience in development and design, which allows the plant to occupy a leading position in its industry.

The company's management pays great attention to safety issues: Tonar equipment is equipped with components and parts of well-known manufacturers and meets all UNECE standards.

Before going on sale, the equipment undergoes serious and long-term tests on its own ATP with maximum loads and in "hard" conditions. During the entire period of testing, a constant analysis of the operational and consumer properties of the equipment is carried out.

Today, the plant produces more than a hundred different models of trailed equipment, which is divided into 4 main areas:

- Main trailer equipment;

- Agricultural machinery;

- Dump trucks and special vehicles for transportation of bulk cargo;

- Repair parts

Sales market

The geography of sales of MZ "Tonar" is constantly expanding, and not only within our vast country. At the moment, one of the priorities of our plant is to enter foreign markets. Already now there are deliveries of trailers to Africa (Ghana, Sudan, Chad, Angola, côte d'ivoire, Senegal, Algeria), Asia, South America, the Middle East, Kazakhstan, Ukraine, Belarus.

Product benefits "Tonar»

- Product benefits "Tonar»

- Fast payback period;

- Execution of individual orders;

- Ultimate endurance techniques: adaptation to the harsh Russian conditions;

- High maintainability;

- Developed service network and spare parts sales network;

- 36 month warranty